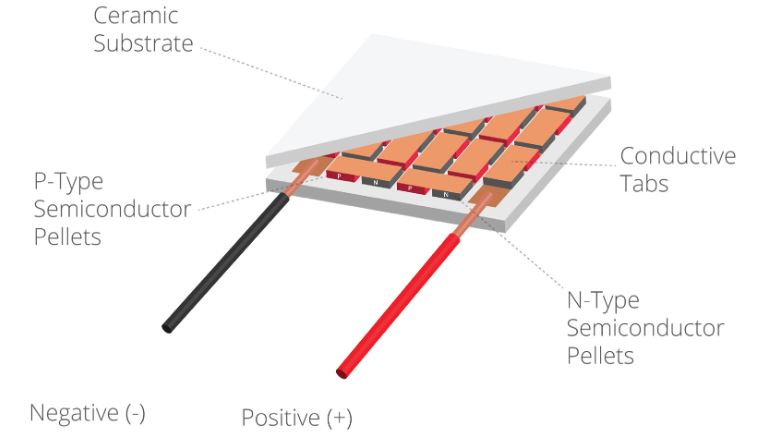

TEC (Thermoelectric Cooler) is a high-performance semiconductor device based on Peltier Effect for active cooling with a DC power supply. A TEC module is made of an array of P-type and N-type semiconductor elements (Bismuth Telluride). These semiconductor elements are electrically connected in series starting with an N-type element connecting to the positive side of the power and ending with a P-type element connecting the negative side of the power. Thermally these semiconductor cooling elements are connected in parallel. The array of electrically and thermally connected cooling elements are contained in between of two ceramic substrates.

When the DC circuit is closed, the majority carriers, electrons are driven from the N-type elements into the P-type elements with thermal energy absorbed from the hot side. The moved thermal energy is efficiently dissipated into the ambient by the heatsink. The TEC acts a heat pump that continues remove the heat from the source and dump it to the heatsink. The process results in the intended effect of cooling of the hot side.

Laird Thermal Systems PowerCycling PCX series TECs are high-performance thermoelectric coolers that use an enhanced module construction for long life operation in thermal cycling applications. The PowerCycling PCX series TECs can handle fast temperature ramp rates and withstand harsh mechanical and environmental conditions, while providing precise temperature control and minimal degradation in performance. The PowerCycling PCX series products of Laird Thermal Systems have been tested per the passing criterion of the following tests.

- Functional Testing – used to validate cooling capacity, temperature differential ∆T, and coefficient of performance (COP)

- End of line Tests – Visual Inspection, AC Resistance Test, and IR Testing

- Die Shear Force – determines the level of shear force that the TEC can withstand.

- High Temperature Storage – determines the effect of prolonged exposure at a high temperature on the TECs.

- Thermal Shock – determines the integrity of the TECs after exposure to extreme high and low temperatures.

- High Temperature & Humidity – determines the effect of prolonged exposure at a constant high temperature and high humidity on the TECs.

- Reverse Power Cycling – determines the effect of electrically induced thermal stresses generated by sudden changes between “positive” and “negative” power conditions to induce 200K rapid temperature cycles.

Features

- High thermal cycling capability

- Precise temperature control

- Solid-state operation

- Boosted performance with next-gen material

- RoHS-compliant

Applications

- Medical

- Medical Storage Chambers

- Medical Diagnostics

- Computerized Tomography

- Positron Emission Tomography

- Cardiovascular Medical Imaging

- Magnetic Resonance Imaging

- Radiation Therapy

- Point of Care Testing

- Medical and Cosmetic Lasers

- DNA Amplification

- Analytical

- Electron Microscopes

- Digital Microscopes

- Centrifuges

- Incubator Chambers

- Liquid Chromatography

- Bath Cooling

- Industrial

- Industrial Laser

- Additive Manufacturing

- Laser Projectors

- Machine Vision

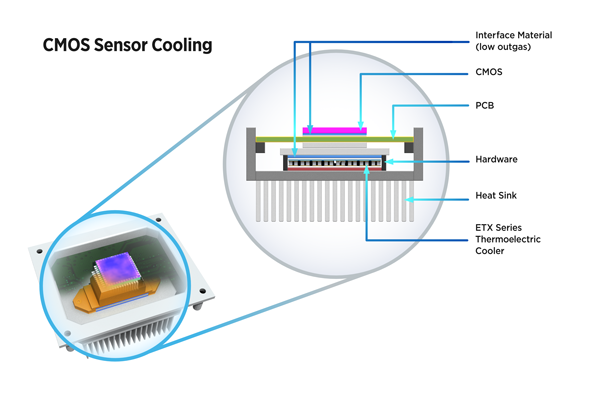

- CMOS Sensors

- Infrared Range (IR) Sensors

- Semiconductor Metrology Equipment

- Semiconductor Fabrication Equipment

- Thermal Test Sockets

- Industrial X-Ray Cooling

- Corrosion Prevention in Cooling Loops

- Telecom

- Optical Transceivers

- Enclosure Cooling

- Base Station Battery Cooling

- Transportation

- Autonomous Systems

- Digital Light Processors

- X-Ray Inspection Systems

- Consumer

- Beverage Cooling

- Optoelectronics

- Lidar Sensors

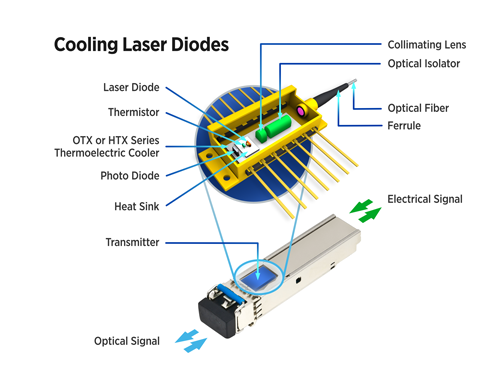

- Laser Diodes

- Security Cameras

Read More: https://www.lairdthermal.com/thermal-applications