Plasma lighting-commonly referred to as Light Emitting Plasma (LEP)-is rapidly becoming a mainstream technology and will soon replace LED and High-Intensity Discharge (HID) lighting in many applications. In these applications, plasma lighting performs better than traditional Illumination source.

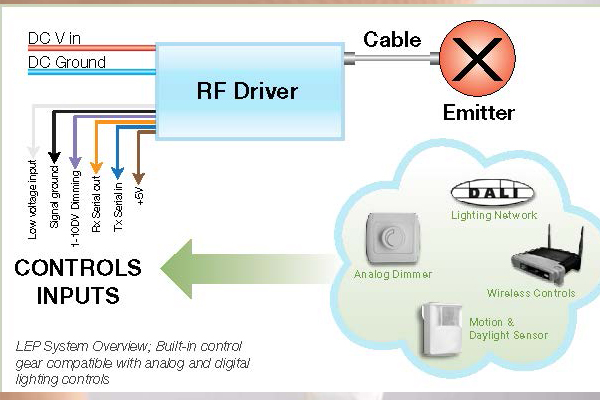

The first step towards the development of commercial scale applications is to overcome the reliability and lifetime limitations of the previous generation of magnetron plasma lamps. This is achieved through the innovation of solid-state plasma lamps, which are powered by radio frequency energy and are based on gallium nitride semiconductor technology. The next step is to help commercial OEMs adapt their product designs to utilize the RF energy generated by silicon-based gallium nitride, making it easier for them to utilize this novel technology. Using the RF energy design toolkit, lighting system designers can now effectively reduce development complexity and cost and shorten the time to market of solid-state plasma lighting – I believe this plasma lighting technology is on the fast track for ready applications in many fields, such as agriculture, automotive, entertainment, medical and sports, etc.

LEP illuminates the future

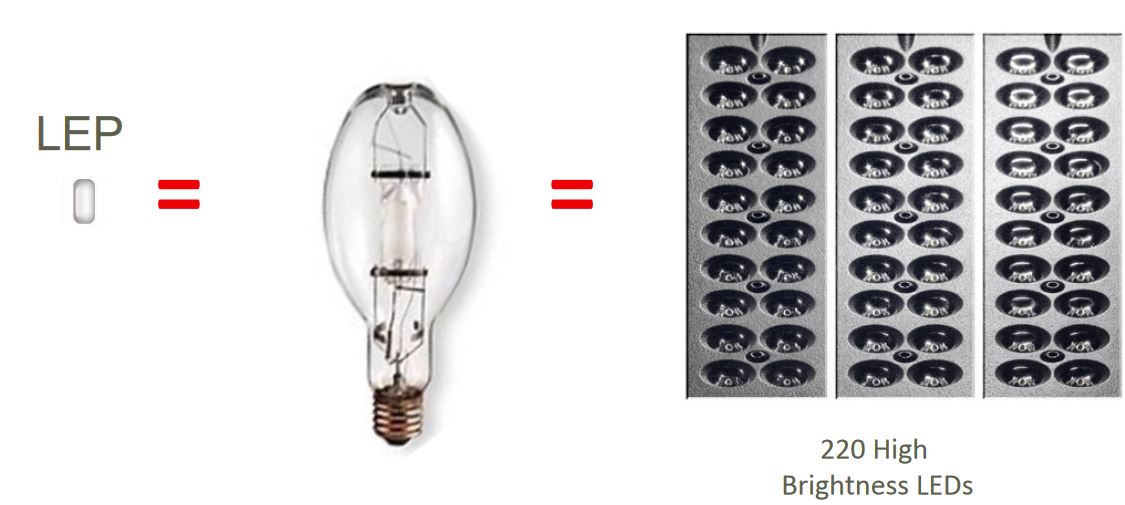

Compared with traditional light sources, one of the main advantages of plasma lighting is the ability to emit a large amount of light from a very small space. LEP is characterized by high lumen density-a fingertip-sized LEP bulb can produce 10,000 lumens of light. In contrast, a high-density LED lamp capable of the same amount of light would require a 100cm x 100cm LED array. Therefore, LEPs are very suitable for vehicle headlights because they can provide much brighter lighting effects than LED, HID and halogen lamps under the same conditions. This ensures increased visibility of the vehicle’s road surface and improved driver/passenger safety. The same benefits can be gain by trains and ships too. LEP is also very suitable for scientific and medical applications, because for these applications, bright, stable, uniform and high-quality light sources are essential, but the space available for the deployment of light sources is limited, which may include operating rooms and medical laboratories, endoscopes Mirror equipment and microscopes, etc.

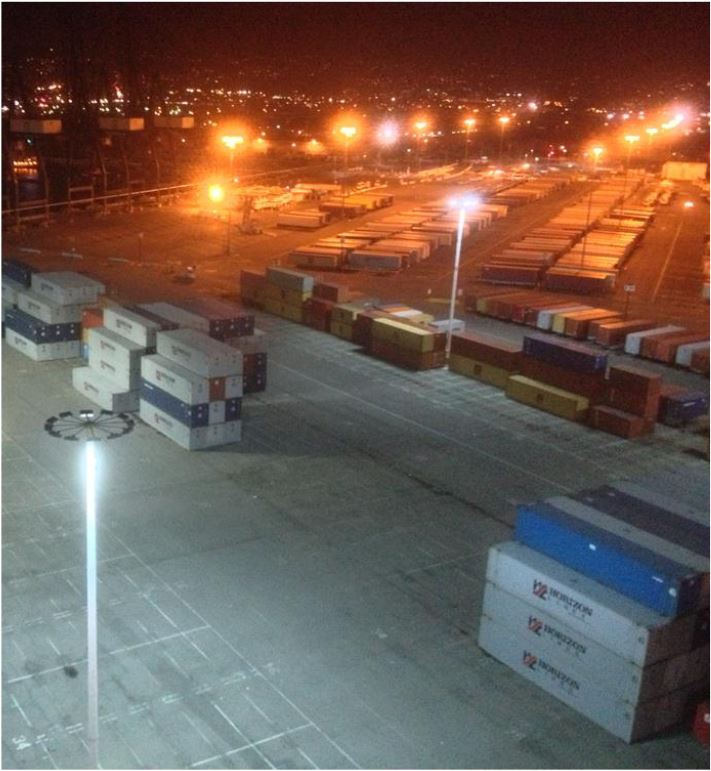

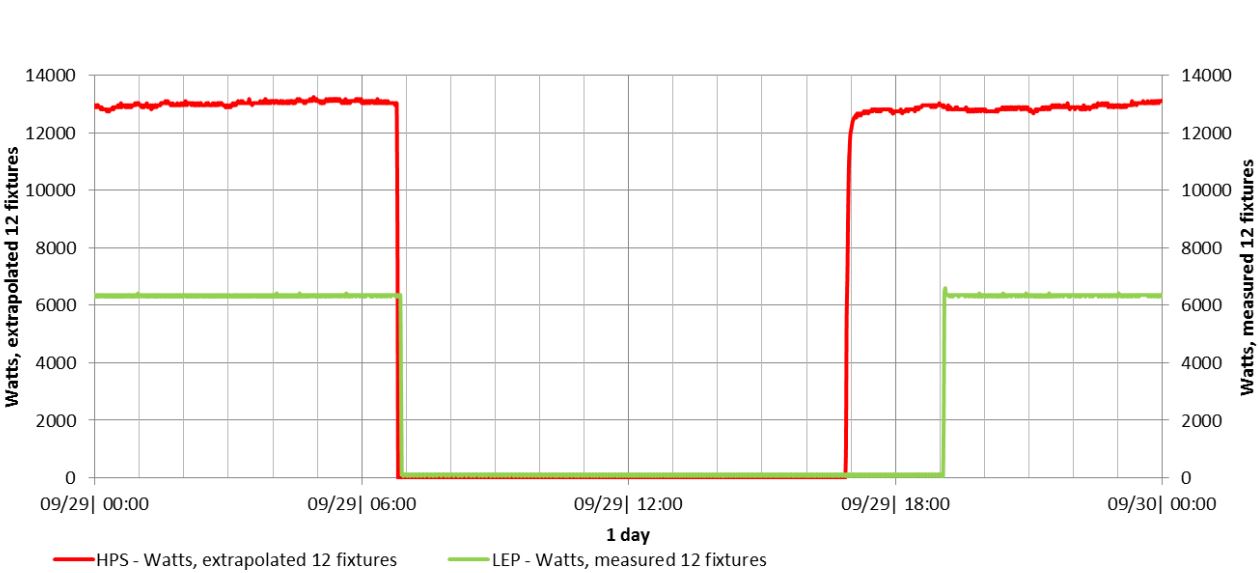

The high lumen density of LEP also makes it an ideal choice to replace LEDs and High-Pressure Sodium lamps (HPS) to achieve large-area lighting in parking lots, warehouses, stadiums, airports and harbors. LEP has a high level of visual acuity and enhanced performance of color rendering, so it also has a leading edge in applications such as outdoor exhibition halls (such as car dealerships), allowing consumers to enjoy a brighter and clearer visual experience. In all of the above large-area lighting applications, the plasma lamp can achieve a high level of visual acuity and uniform light distribution, which ensures that everyone nearby can better recognize the surrounding environment. This can increase the safety factor for workers and pedestrians, while helping to create higher quality workplaces.

LEP Grow Light

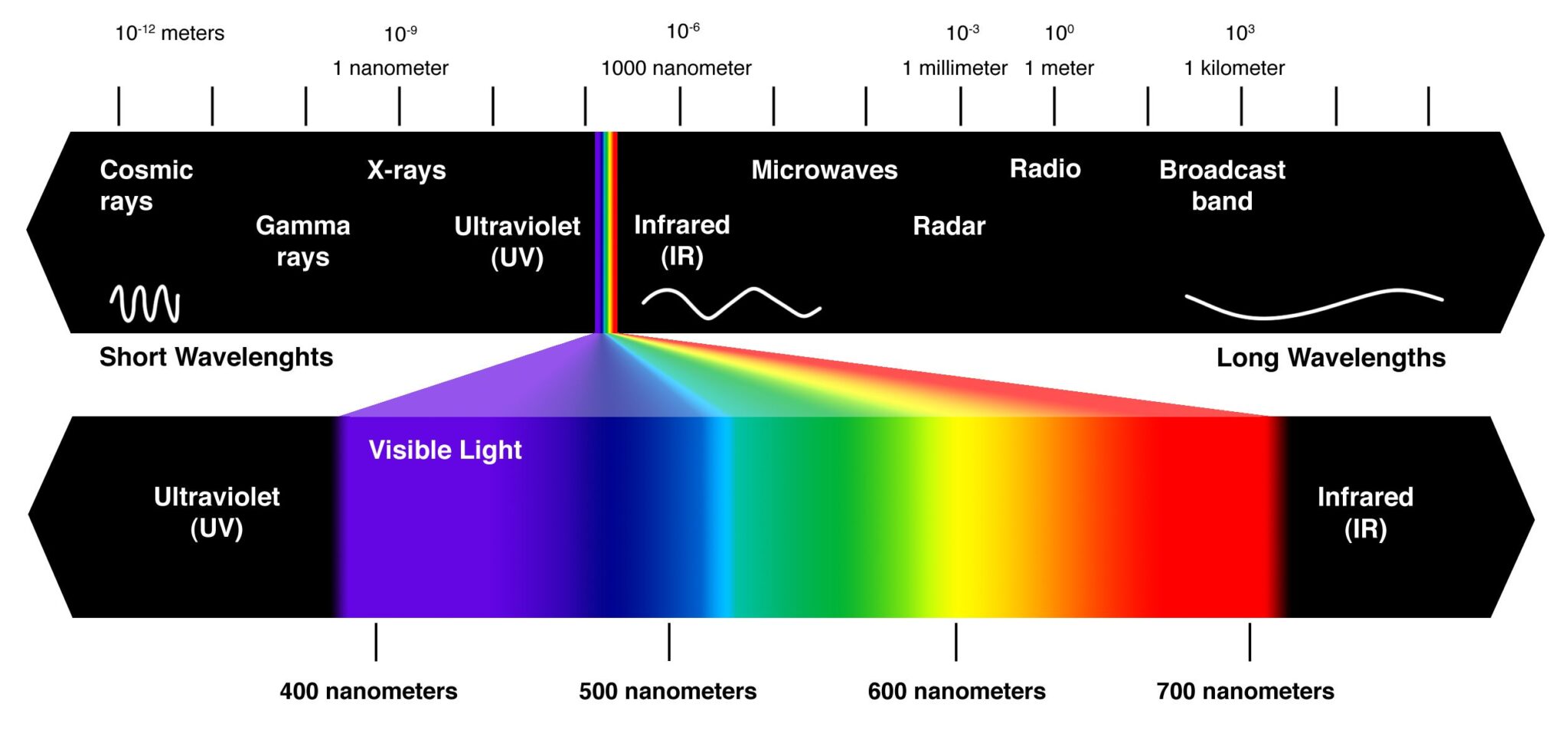

One application where plasma lighting has developed significantly is gardening. LEP bulb can emit continuous full-spectrum light similar to natural light (including ultraviolet UVA and ultraviolet UVB) when it is by the electromagnetic field, without the need for secondary fluorescence conversion like the light used by LEDs. At the time of emitting light, the inside temperature of the LEP bulb is up to 6000K that is quite close the 5777K temperature inside the Sun. Therefore, no matter large or small growing environment, they both can be benefited from the unique performance of LEP. The plasma grow lamp can also adjust the lighting to different frequencies and spectra. There are many ways to promote plant growth according to the type of light emitted by specific parts of the plant. Therefore, the adjustability of the spectrum is extremely useful for growing healthier plants, fruits, vegetables, etc., and can also help improve the efficacy of botanical drugs.

LEP Cost and reliability

Designers of the new generation of lighting systems certainly also focus on energy efficiency and related OPEX (Operating Expenses) considerations, as well as reliability issues that may lead to higher maintenance costs. After all, it is most beneficial to produce brighter, higher-quality full-spectrum light only when implemented in a cost-effective manner. The light source efficiency of LEP (that is, the lumens produced per watt) is up to 20% higher than that of HID light sources, which is comparable to the efficiency of LED light sources. Since LEP bulbs do not use electrodes (the performance of the electrodes degrades over time and is often the source of failure for many traditional light sources), they are quite reliable and have a service life of up to 50,000 hours.

The advantages of solid-state plasma lighting are in many aspects, which makes LEP an attractive choice for various future applications. In the next blog post, we will deeply explore the many advantages of LEP over LED, and find some common points of these two emerging technologies through comparison. We will also carefully study how silicon-based GaN technology affects the corresponding design considerations for LEP and LED lamps.