Honeywell’s new Transportation Attitude Reference Sensor TARS-IMU (Inertial Measurement Unit) is a packaged sensor array designed to report vehicle angular rate, acceleration, and inclination for demanding applications in industries such as heavy duty, off-highway transportation. The TARS-IMU device is expected to enable autonomous vehicle characteristic and enhances efficiency and productivity by acquisitioning and reporting important data required for automating and monitoring movements of heavy-duty off-highway vehicles. The sensor is integrated with the vehicles’ electronic control modules (ECMs) to provide key information about the movement of the machine. The sensor fusion algorithm can be customized for specific vehicle applications through on-board firmware, allowing movement data to be filtered for extraneous environment and vehicle movements.

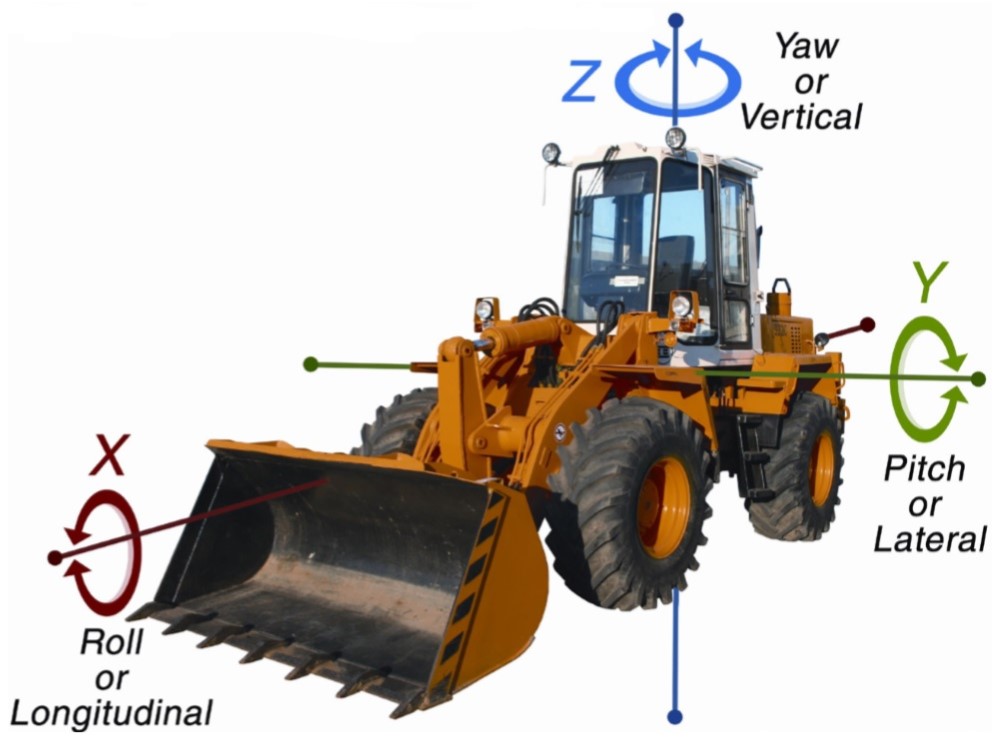

Agricultural vehicle operators often encounter the risk of rollovers due to rolling hills and soft ground, which makes the safety of operators one of the key priorities. At the same time, improving productivity is another important task the farm operators must achieve. As the need for increased safety and production efficiency continue being the top concerns, the use of 6 DOF (six degrees of freedom) inertial measurement units (IMUs) as part of the vehicle controls integration becomes a trend for agricultural equipment manufacturing.

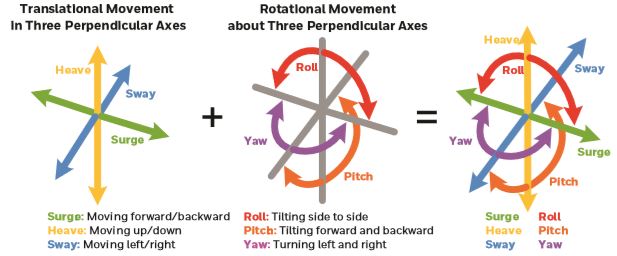

IMUs (Inertial measurement units) that incorporate multiple accelerometers and gyroscopes to precisely sense motion and position provide measurements for translational (up/down, left/right, forward/backward) as well as rotational movement (roll, pitch and yaw). These measurements provide important equipment data that are key to accurate and precise control of the vehicle’s performance and safety. The benefits are obvious that we gain increased vehicle accuracy, safety and stability as well as improved productivity.

One application of Honeywell TARS-IMU is the work-site ground preparation. When programmed specifically with a certain customer’s parameters, the TARS-IMU installed on a loader can provide real-time information about the loader’s position in respect to the inclination. The machine’s ECU processes the data sent by TARS-IMU and provides feedback to the operator where the machine is located with respect to the inclination. Such indication allows the operator to make real-time adjustments to grade as the loader is in motion. With Honeywell’s TARS-IMU, the operators can achieve a level of 0.6o equivalent to a 1% of grade for proper water run-off.

Another application of TARS-IMU, for example, can be in traction control. The device monitors the vehicle’s movement and captures the momentary loss of traction and feeds the information to the vehicle’s ECM which is programmed to rapidly respond to this error by reducing power to the wheel to prevent further wheel slippage and possible severe accident.

Graham Robinson, the president of Honeywell ‘s Sensing and Internet of Things business, said “Heavy-duty machinery, such as construction vehicles, require skilled, experienced operators to perform complex tasks deftly. An operator error can impede the project schedule or even put worker safety at risk. Our new series of transportation sensors can enable ‘intelligent vehicles’ by allowing for the autonomy of individual equipment functions. This minimizes the risk of operator errors and enables precise movements in challenging work environments.”

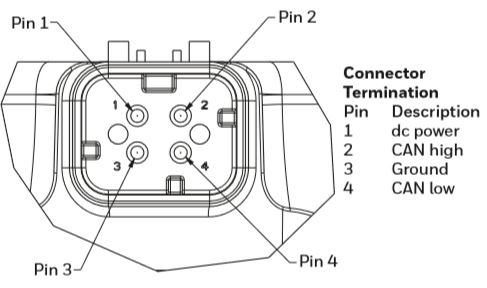

TARS-IMU accommodates both 5V and 9V to 36V vehicle power systems. While communication is carried to the vehicle through industry standard CAN J1939 connectivity.

The Honeywell TARS-IMU sensor can be applied to many applications, such as equipment control, linear position, linkage tracking, bucket control, working monitoring, vehicle stability control, operator assisted control and performance and output control, etc.