Bosch Connected Industrial Sensor Solution (CISS) is a small robust multi-sensor device for harsh industrial environments, which integrates a gyroscope, accelerometer, magnetometer, temperature/humidity/air pressure sensor, microphone, and light sensor. CISS is a viable solution for Industry 4.0 applications in following cases:

Condition monitoring:

Due to its compact size and robust design, the CISS allows you to introduce IoT applications into rough industrial environments, provides increased efficiency, safety and saves cost for new deployment;

Digital twin:

The CISS delivers crucial data for digital twin applications, which is the basis for improvement of the Overall Equipment Efficiency (OEE). If there are any issue, the system can immediately start the problem-solving process on the digital twin. This provides the advantage of reacting faster during the maintenance of the real product.

Machine doctor:

The CISS offers the flexibility of running quick fixes or checkups. In addition to long term machine maintenance, the CISS can easily help measure relevant parameters in the plant (e.g. vibration or temperature). All we need to do to check up on a machine would be: to mount the device, measure and interpret the sensor data, ad then receive an impression of the inner workings of the machine. From the sensor information we can determine what issues the machine may be facing and can solve them.

Predictive maintenance:

The CISS can help save time and cost that relate to machine downtime. The CISS can be used on new machines or on retrofitted existing machines for compliance with Industry 4.0.

Engineer can activate or deactivate each sensor individually and configure the sensor’s sampling rates and thresholds to suit a variety of applications. The CISS is a robust multi-sensor device based on MEMS (Microelectromechanical Systems) and features a 32-bit Arm Cortext-M3 microcontroller with 1MByte of internal flash, as well as a Bluetooth low energy (BLE) radio and USB connectivity for data transmission.

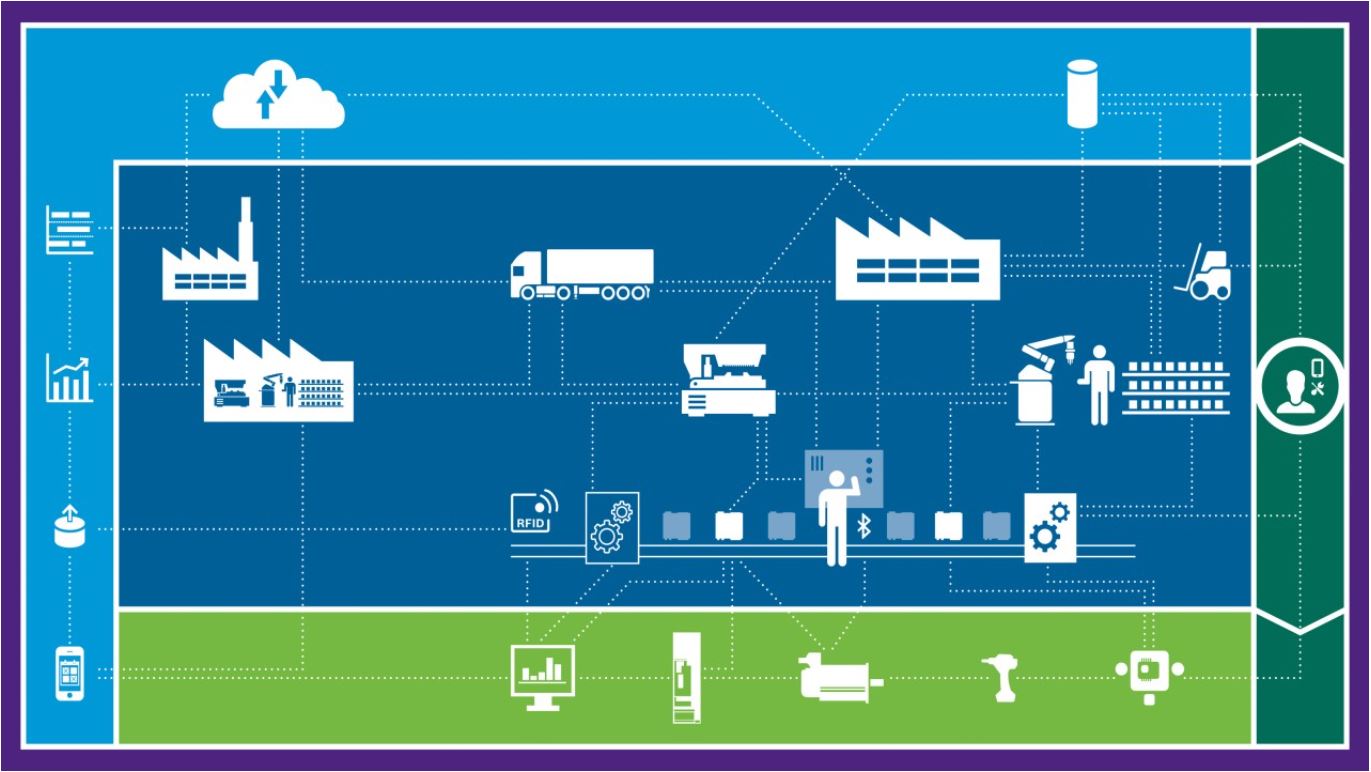

The CISS provides valuable data to optimize maintenance processes and enhance productivity and can be integrated to wide range of hardware-agnostic gateways and clouds. The device allows for monitoring of multiple conditions simultaneously to provide improved predictive maintenance, while both live and historic data can be supplied over the Virtual CISS app or the cloud.

The CISS can be integrated as initial equipment in new machines, machine modules, plants and as a retrofit sensor solution to upgrade existing equipment and make it ready for Industry 4.0. The benefits of applying the CISS solution can be huge:

- A multiple-sensor solution: the CISS is easy to use. As a multi-sensor device, the CISS is suitable for various machines and applications and allows several problems to be analyzed simultaneously.

- Increased efficiency: the immediate recognition of deviations and the ability to react instantly avoids consequential damage, unnecessary downtimes and spoilage production thus significantly increases efficiency.

- High protection class: the CISS is designed especially for sing the application in harsh environments. Protection class IP54 makes the CISS a reliable partner for industrial sectors, processes and applications.

- Broad temperature range: an operating temperature range from -20C to 80C makes the CISS the perfect solutions for a huge variety of industrial uses cases.

Read more at: https://www.bosch-connectivity.com/products/connected-industrial-sensor-solution/