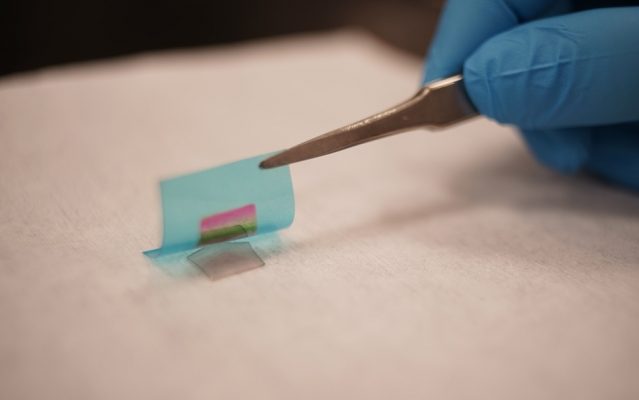

October 8, 2018, MIT News, MIT researchers have devised a way to grow a single crystalline compound semiconductor on its substrate through two-dimensional materials. The compound semiconductor thin film is then exfoliated by a flexible substrate, showing the rainbow color that comes from thin film interference.

This study opens the route to flexible electronics made from exotic materials. It’s shown as a cost-effective method that produces semiconducting thin films from materials that outperform traditional semiconductor material silicon. Silicon is an abundant element and can be found in various forms in rocks, clay, sand and soil. Since it’s high availability and low cost, silicon has been the dominant semiconductor material used in most electronic devices, including sensors, memories, solar cells and almost all the integrated circuits in our computers and smartphones.

Now, the engineers from MIT have found a cost-effective way to develop a technique to fabricate ultrathin semiconducting films from a host of exotic materials other than silicon. To demonstrate the technique, the researchers at MIT have fabricated flexible films made from gallium arsenide, gallium nitride, and lithium fluoride, which outperform silicon but have not been practically in production due to their extremely high cost to fabricate. With the new technique developed by MIT engineers, fabrication of flexible thin films from these exotic materials becomes cost-effective. It can be practically used to produce electronics made from any combination of semiconducting elements that can outperform the current silicon-based devices.

Jeehwan Kim, the Class of 1947 Career Development Associate Professor in the department of Mechanical Engineering and Materials Science and Engineering envisions the technique can be used to manufacture low-cost, high performance devices such as flexible solar cells, and wearable computers and sensors.

Details of the new technique are reported today in Nature Materials. In addition to Kim, the paper’s MIT co-authors include Wei Kong, Huashan Li, Kuan Qiao, Yunjo Kim, Kyusang Lee, Doyoon Lee, Tom Osadchy, Richard Molnar, Yang Yu, Sang-hoon Bae, Yang Shao-Horn, and Jeffrey Grossman, along with researchers from Sun Yat-Sen University, the University of Virginia, the University of Texas at Dallas, the U.S. Naval Research Laboratory, Ohio State University, and Georgia Tech.